Galvanized Steel Pipe Manufacturing Process for Greenhouse Structures

10/29/2025

Hongqiangsheng

Galvanized steel pipes are one of the most widely used structural materials in modern greenhouses.

They offer excellent corrosion resistance, high strength, strong weather durability, and a long service life — making them the key supporting components of greenhouse structures.

Raw Material Selection

- Steel Strip Material:High-quality low-carbon steel (Q195, Q235, or Q355) with good weldability and plasticity.

- Surface Requirements:The surface of the strip must be smooth, free of cracks, rust, and other defects.

- Thickness Range: Generally between 1.5 mm and 3.0 mm, depending on the greenhouse span and design requirements.

Production Process Flow

Steel Coil Uncoiling → Leveling → Forming → High-Frequency Welding → Inner & Outer Seam Treatment → Sizing & Straightening → Cutting → Hot-Dip or Cold Galvanizing → Inspection → Packing

Detailed Process

- Uncoiling & Leveling

Steel coils are placed on the uncoiler and leveled to remove internal stress, ensuring stable forming quality.

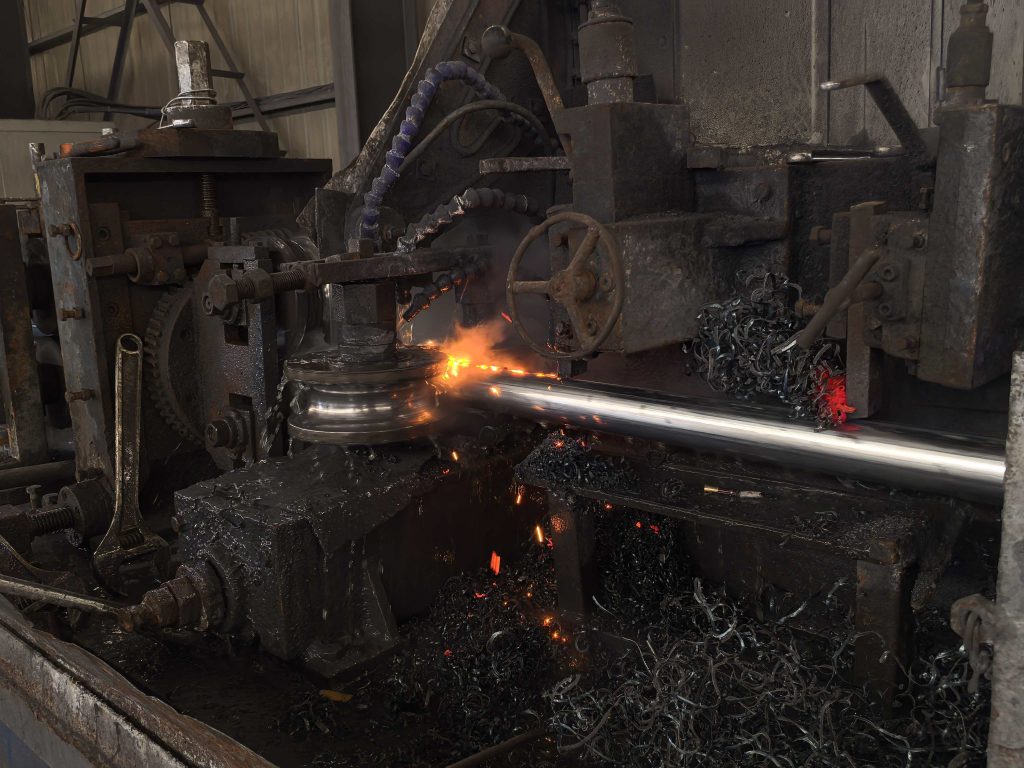

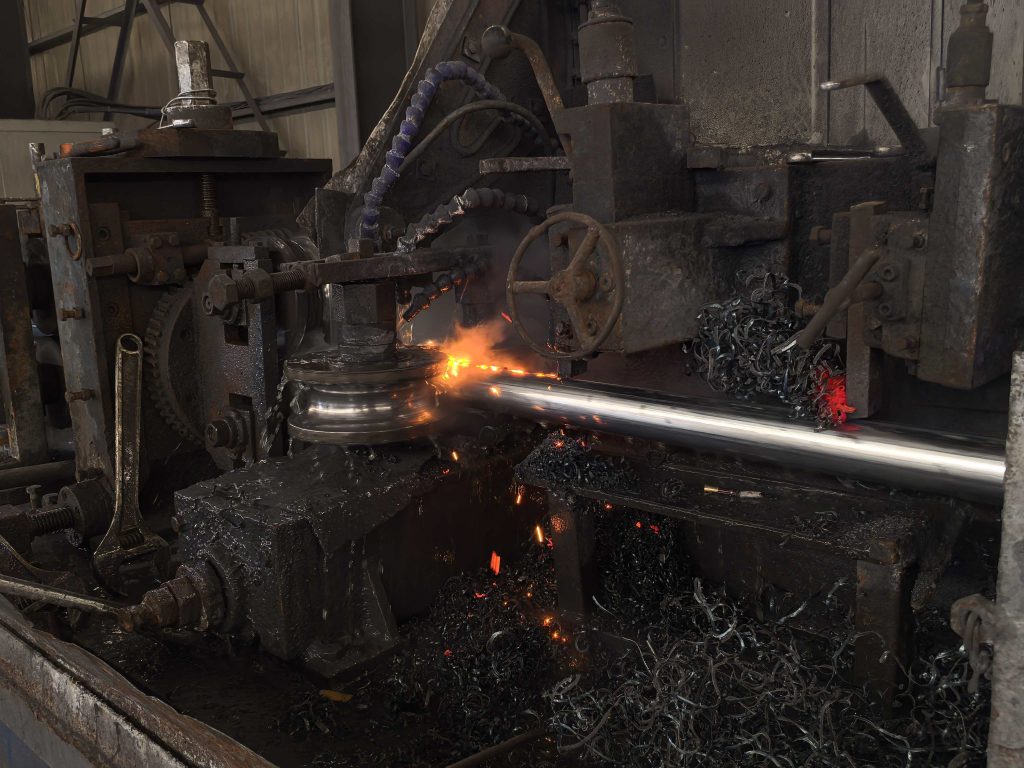

- Forming & Welding

The leveled steel strip is gradually rolled into round or square pipes through rollers.

High-frequency induction welding (HF welding) ensures smooth and firm welds with no burrs.

- Weld Seam Treatment

The inner and outer weld seams are trimmed to remove excess welding material, ensuring a smooth internal surface to prevent rust or water accumulation.

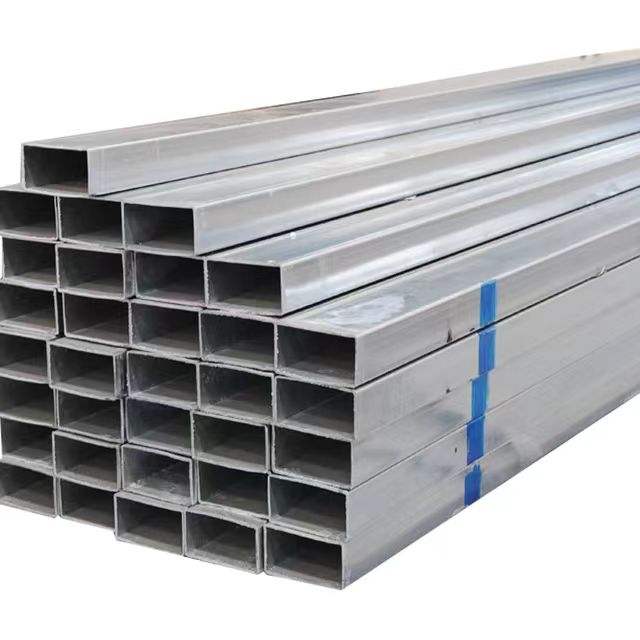

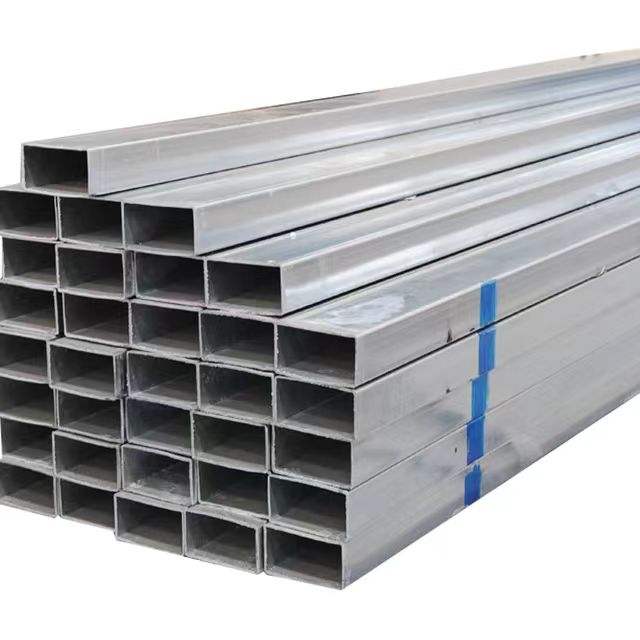

- Sizing & Straightening

Pipes are precisely shaped to ensure dimensional accuracy within ±0.5 mm and a straight, even appearance.

- Cutting

Pipes are cut to specified lengths, typically 6 m or 8 m, depending on customer requirements.

- Galvanizing Process

Two methods are commonly used:

— Hot-Dip Galvanizing:

Pipes are immersed in molten zinc at about 450 °C, forming a strong alloy bonding layer.

Zinc layer thickness ≥ 60–80 μm, service life: 15–25 years.

— Cold (Electro) Galvanizing:

A uniform zinc coating is applied through electroplating.

Zinc layer thickness 10–20 μm, more economical, suitable for cost-effective greenhouse projects.

- Inspection & Packaging

Inspection items include surface quality, dimensions, zinc layer thickness, adhesion, and weld strength.

Pipes are bundled or wrapped with anti-rust film for convenient transportation and handling.

Key Features

- Superior corrosion resistance — Zinc coating protects against oxidation and moisture.

• High structural strength — Excellent toughness, capable of withstanding wind and snow loads.

• Long service life — Hot-dip galvanized pipes can last over 20 years outdoors.

• Easy installation — Suitable for welding, bolted, or insert-type connections.

Application Fields

- Smart greenhouses, flower houses, vegetable nurseries, and eco-restaurants

- Livestock sheds, shading structures, and rainwater collection shelters

High-quality galvanized steel pipes form the foundation of a strong and durable greenhouse.

Through scientific manufacturing processes and strict quality control, each pipe ensures superior strength, corrosion resistance, and longevity — providing reliable support for modern agricultural greenhouses.